Production Lines

PLTCM (Pickling Line and Tandem Cold Mill) CGL (Continuous Galvanizing Line) CCL (Painting Line) CAL (Continuous Annealing Line) ECL (Electrolytic Cleaning Line) BAF (Batch Annealing Furnace) Line (Tempering And Double Cold Reduction) ETL (Electrolytic Tinning Line)In the Continuous Galvanizing Line (CGL), the Pickled, Rolled or Tempered Cold coils are annealed in the desired quality depending on the customer’s choice, and zinc plated in the desired weight using the hot-dipping method. Additional processes may take place depending on the customer’s choice, such as Tempering, Passivation, Badging (Logo) and Electrostatic Oiling.

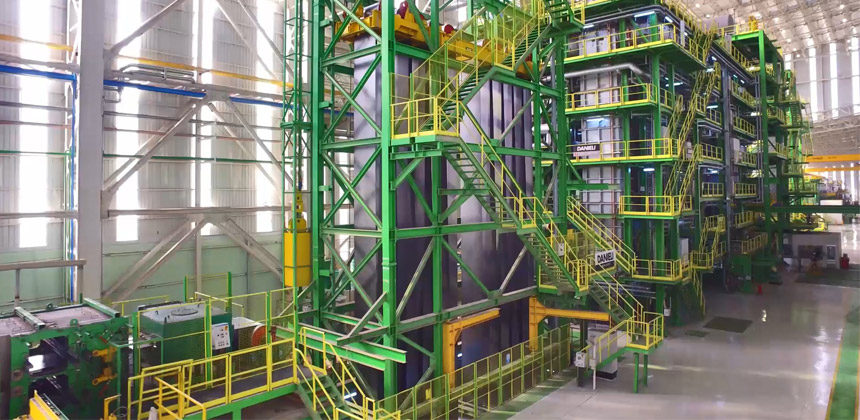

| The CGL’s Features; | |

| Supplier | Danieli |

| Steel Qualities | CQ, DQ , DDQ, EDDQ (IF) , HSS up to DP600 |

| Min – Max Thickness | 0,2 mm – 3,0 mm |

| Min – Max Width | 700 mm – 1300 mm |

| Plating Weight | 60-600 g/m² GI

40-180 g/m² GL (Future Project) 90-300 g/m² Zn-Mg (Producible) |

| Maximum Line Speed | 200 mpm |

| Production Capacity | 400.000 t/year |